Demand

One of the most important and most difficult things you can do when designing your compressed air system is to determine the true demand in your system. Air demand will fluctuate beyond the predetermined average demand. If the actual demand is known, storage and distribution systems can be designed to meet demand without the installation of additional compressors. The most precise way to determine demand in the system is to monitor the air flow using a flow meter, which would normally be positioned in the main headers. For small, simple systems, the ratio between loaded and unloaded compressor running time can be indicative of average demand over a long periods of time. Often, leakage and artificial demand represent a substantial portion of the overall demand. There are various methods to stop leaks. Excess volume of compressed air created for unregulated users is called artificial demand. It occurs when greater line pressure than necessary was supplied. It includes the following:

• all unregulated consumption, including appropriate and inappropriate production usage

• open blowing

• leaks

• point of use with regulators adjusted to their maximum setting

• tooling

These applications track the supply pressure as though no regulators were being used.

The artificial demand challenge can be resolved by positioning a regulator at the point of use or at the beginning of the distribution network. Operating pressure requirements, compressed air requirements, and the duty cycle of individual equipment must all be considered when establishing demand for your system. Air quality: Different applications demand different levels of compressed air quality. With each level, the cost to produce the compressed air increases. Therefore, it is essential to meet, but not exceed the level required by your particular application. If different levels are required for different applications within the plant, it is more cost-effective to treat smaller amounts of compressed air for the application with the highest level of quality requirements, than to treat the whole air supply.

Supply

The compressed air supply must always meet the compressed air demand by utilizing sufficient storage and correct distribution. Properly sized compressors and purification equipment will aid in meeting demand with supply. If the supply, storage, and distribution are not in sync, excessive pressure fluctuation will occur. Most compressors are controlled by line pressure. A drop in pressure normally signifies a demand increase. This is corrected by increased compressor output. A rise in pressure usually indicates a decrease in demand, which causes a reduction in compressor output. To accommodate the fluctuating demand, a load/no load or constant speed control can be used to run the compressor at full load or idle. Either a single compressor or a multiple compressor installation, which can be centralized or decentralized, can provide the entire plant supply. There are three other types of compressor control systems:

- Auto-dual control: Most traditional modulating controls throttle the capacity 30%-50% before fully unloading the compressor. This type of modulation is known as auto-dual control. It combines start/stop and constant speed control into a single control system. Auto-dual control automatically selects the most desirable control method and runs the compressor in constant speed control. When the compressor unloads, an unloaded run timer energizes, which usually has a time range of 5 to 60 minutes. If the compressor does not reload, the timer will shut the compressor off. The compressor will restart and reload when the pressure switch senses low pressure.

- Sequencing: Sequencing is also known as a central controller. This has the advantage of little cost per compressor and is usually available for systems with up to 10 compressors. A sequencer should have a single pressure transducer in the airheader. Logic should maintain a target pressure within +/- 5 psi. The sequencer should automatically start and stop compressors, as well as load and unload them. The control should be set to rotate the order of loading and unloading to optimize compressor combinations for different demand conditions.

- Lead/Lag: Lead/lag controls are typically found on reciprocating compressors. When there are two compressors in the system, one compressor can be set as the lead compressor, and the other as the lag compressor. When the pressure drops to a certain point on the lead compressor, the lag compressor will then take over. These can also be switched so that the other compressor is the lead compressor.

Storage

All devices containing compressed air make up the storage system. Adequate storage is essential. It represents available energy that can be released or replenished at any time it is needed. The air receiver tank normally makes up the majority of the total storage capacity of the system. If this tank is properly sized, excessive cycling will be prevented, and adequate storage capacity for any peaks in demand will be provided. In the distribution system, there will periodically be large volume demands, which will rapidly drain the air from surrounding areas, and cause pressure levels to fall for surrounding users. However, strategically located receivers in the system can supply these abrupt demands and still provide a consistent air flow and pressure to the affected areas. The total storage capacity needed is dependant upon the amount of excess demand in cubic feet, the available pressure differential between the flow controller, the system and compressor start-up time, and the time available to replenish stored compressed air.

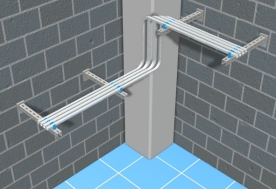

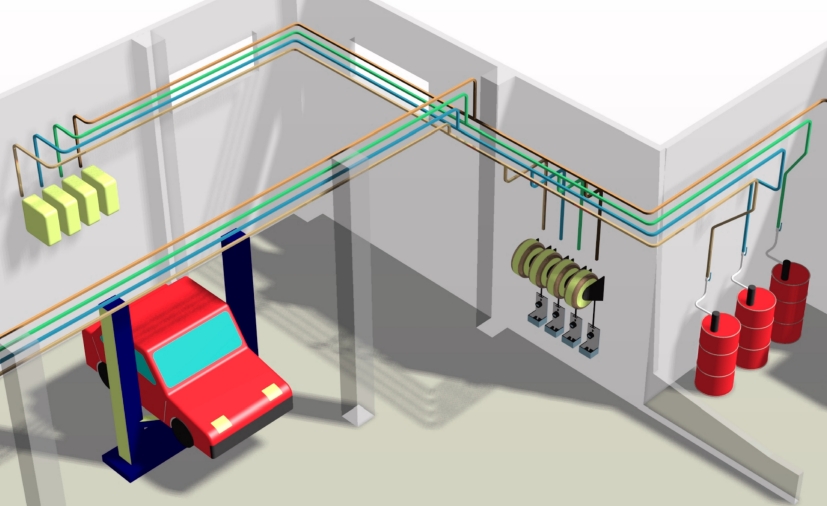

Distribution

The distribution system is the link between supply, storage, and demand. Ideally, the distribution system will allow the required air to flow with minimum pressure drop. It will supply an adequate amount of compressed air at the required pressure to all of the locations where compressed air is needed. The compressed air travels through a network of pipelines, but the flow creates friction and results in pressure drop. The pressure drop should never exceed 1-2 psi (0.07 - 0.14 bar). The longer and smaller diameter the pipe is, the higher the friction loss. To reduce pressure drop effectively, a loop system with two-way flow can be used. Pressure drop caused by corrosion and the system components themselves are important issues. These typically range from 5-25 psid (0.34 - 1.7 bar) and their control is essential for the efficiency of the system.

Installation

To effectively control and manage the compressed air system, the system layout must be considered. Sufficient ventilation, foundation and compressor room requirements must be met, and appropriate piping materials used. Compressor intakes located outdoors should be a minimum of 10 feet (3 meters) above grade. Proper ventilation may be achieved through natural ventilation, forced ventilation with an exhaust fan, ducted ventilation to the outside with or without a recirculating damper, as well as by mixing warm air with cold intake air, or venting an exhaust air duct to the outside during summer (space heating during winter). Foundation requirements apply only to larger reciprocating compressors, but all compressors should have their own clean, cool room. Piping must be durable enough for existing work conditions, provide minimum possible pressure loss and leakage, and be easy to maintain.

Maintenance

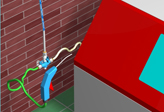

Preventive maintenance is the most important step you can take. Leaks are one of the biggest maintenance issues and can be very expensive. For example, one ¼" (6.35 mm) diameter opening equals 100 CFM(2.8 m3/min) at 90 psig (6.2 bar). This is equivalent to running a 25 horsepower (18 kW) compressor. However, developing a formal program to monitor and repair leaks can control or prevent them. If a leak goes undetected, it can eventually cause the entire system to have to be shut down. A well-maintained compressor, in addition to having less downtime and repairs, will save on electrical power costs as well.

Condensate Control

Moisture in the form of liquid and vapor is in compressed air as it leaves the system. The system can lose productivity and require significant maintenance if the moisture and other contaminants are not removed properly. Purification devices have been developed to help remove some of the contaminants from the system. As pneumatic applications and compressed air systems become more sophisticated, the proper selection of these devices is crucial. The most critical devices for condensate control are the coalescing filter, drain valve, air dryer and after filter.

Note: All compressor condensate is to be disposed of in accordance with all local, state and federal regulations