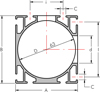

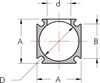

Square pipes:

HBS was the first modular air line system created by TESEO at the beginning of the 90's with a wide range of diameters, up to an inner diameter of 110 mm.

HBS was the first modular air line system created by TESEO at the beginning of the 90's with a wide range of diameters, up to an inner diameter of 110 mm.

It is made by profiles and accessories in aluminium capable of distributing compressed air with a maximum pressure of 15 bars, vacuum and other non dangerous gases.

The sealing is guaranteed by common "O" rings; the connection of the different components can be simply done by tightening the Allen screws on the fixing plates.

The smoothness of the internal surface ensures low air friction and guarantees high performance in terms of flow rate and pressure reduction.

HBS is particularly suitable for the installation of the main distribution line and manifolds on machines or automatic lines.

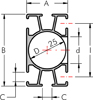

MODELS:

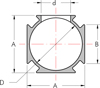

HBS25: The smallest diameter of the range, ideal for installing rings where small flow rates are required.

HBS25: The smallest diameter of the range, ideal for installing rings where small flow rates are required.

HBS32: The first diameter created in the range, and is currently the one with the most Km installed.

HBS32: The first diameter created in the range, and is currently the one with the most Km installed.

HBS50: The intermediate diameter also used to create manifolds in use aboard machines.

HBS50: The intermediate diameter also used to create manifolds in use aboard machines.

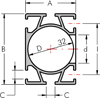

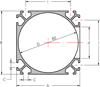

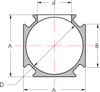

HBS63: The first diameter to have 4 useable sides with the possibility of various sized outlet applications.

HBS63: The first diameter to have 4 useable sides with the possibility of various sized outlet applications.

HBS80: The first diameter to gave 4 useable sides which are exactly the same and perfectly simmetrical.

HBS80: The first diameter to gave 4 useable sides which are exactly the same and perfectly simmetrical.

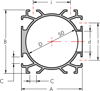

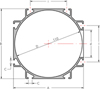

HBS110: The latest diameter of this range to be created, it's and important diameter which is ideal for creating installations for which an elevated flow rate is required

HBS110: The latest diameter of this range to be created, it's and important diameter which is ideal for creating installations for which an elevated flow rate is required

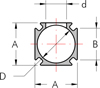

AP is the latest generation of modular piping system developed by TESEO, available in 20, 25, 40 and 50 mm diameters with a wide range of accessories.

AP is the latest generation of modular piping system developed by TESEO, available in 20, 25, 40 and 50 mm diameters with a wide range of accessories.

The pipes are in extruded aluminium and are connected to fittings and accessories, equipped with "O" rings, with the exclusive dovetale clamping and joining system patented by TESEO.

AP can handle compressed air up to 15 bars pressure, vacuum and other non dangerous gases. It is suitable for the installation of column drops, small distribution ringmains and manifolds on machines or control panels.

The assembly is easy and very fast with the use of simple tools, without threading or welding any component. By simply drilling the profile and applying an outlet plate, you can immediately extract the fluid power where needed, at any moment, and even when the installation is already completed.

MODELS:

AP20: The smallest diameter, the first diameter born in this range, ideal for the

creation of drop columns for general use.

AP20: The smallest diameter, the first diameter born in this range, ideal for the

creation of drop columns for general use.

AP25: The intermediate internal diameter ideal for creating small distribution rings,

it is particularly adapted to the distribution of oil.

AP25: The intermediate internal diameter ideal for creating small distribution rings,

it is particularly adapted to the distribution of oil.

AP40: The latest diameter to join the AP family.

AP40: The latest diameter to join the AP family.

AP50: The largest of the AP pipe work which permits the construction of medium sized

installations with the technical characteristics of the AP range.

AP50: The largest of the AP pipe work which permits the construction of medium sized

installations with the technical characteristics of the AP range.